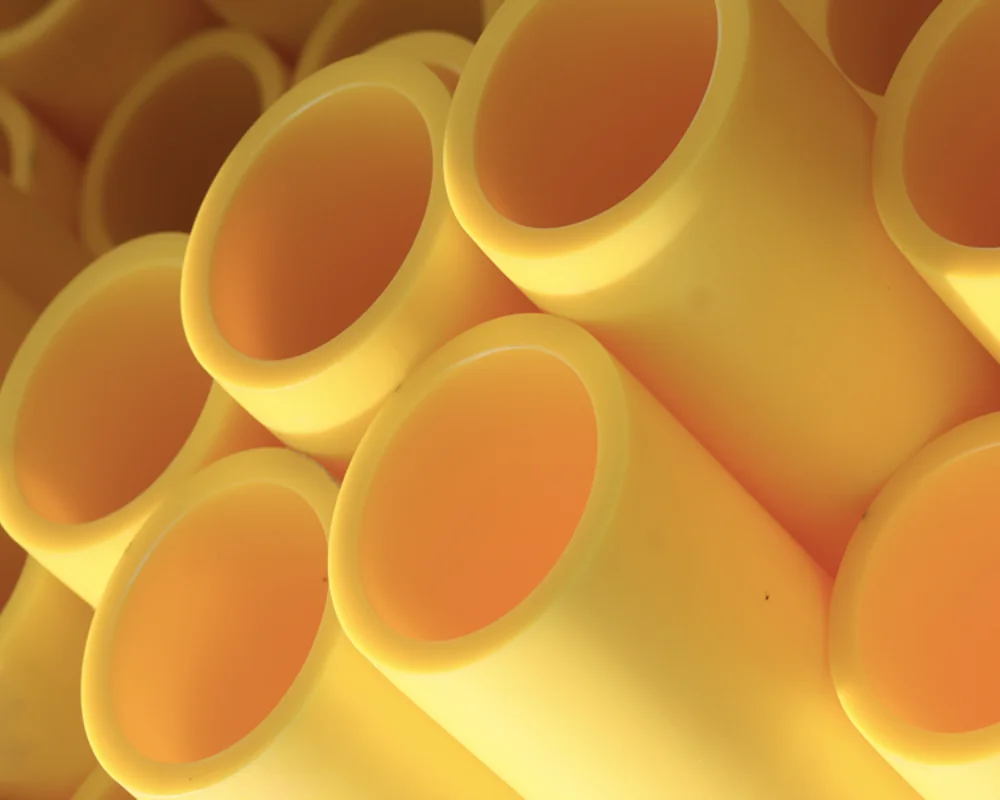

MDPE Pipes

MDPE Pipes are produced using bimodal cadmium-free imported raw material and undergo comprehensive testing through a fully integrated Quality Assurance System (QAS). This system ensures that the pipes meet high-performance standards consistently, covering all aspects from raw material selection to final product testing, including both destructive and non-destructive testing.

ISO & BIS Standards:

These pipes comply with various international standards such as ISO 4437, BS 7281, DIN 8074/75, and the BIS Standard IS: 14885:2001.

Material:

The pipes are made from Medium Density Polyethylene (MDPE) PE-80 and PE 100, which are specifically selected for the production of gas pipes.

Product Range:

MDPE Pipes are manufactured in a range of sizes, from 20mm to 500mm in outer diameter, covering all pressure ratings. The pipes are color-coded to indicate their specific usage, such as yellow for gas, orange for petrol, and blue for water. Customization options are available to meet the specific requirements of individual gas customers.

Salient Features:

Polyethylene Pipes have gained worldwide recognition for natural gas distribution at 4 Bar Pressure, owing to their exceptional technical and operational advantages as a pipe material.

- Flexibility: Easy to handle

- Corrosion Resistance: Reliable and tough, even in aggressive soils

- Fusion Joints: High integrity and reliability

- Lightweight: Significantly lighter than metal pipes

- Crack Resistance: Excellent resilience to subsidence, traffic vibrations, point loading, and marshy ground

- Homogeneous: Leak-free joints

- Installation: Low installation costs